- X-Pact® Centerline Control improves rolling stability and minimizes manual interventions in the hot strip mill

- High customer satisfaction reflects the strong partnership and shared vision for innovation and excellence

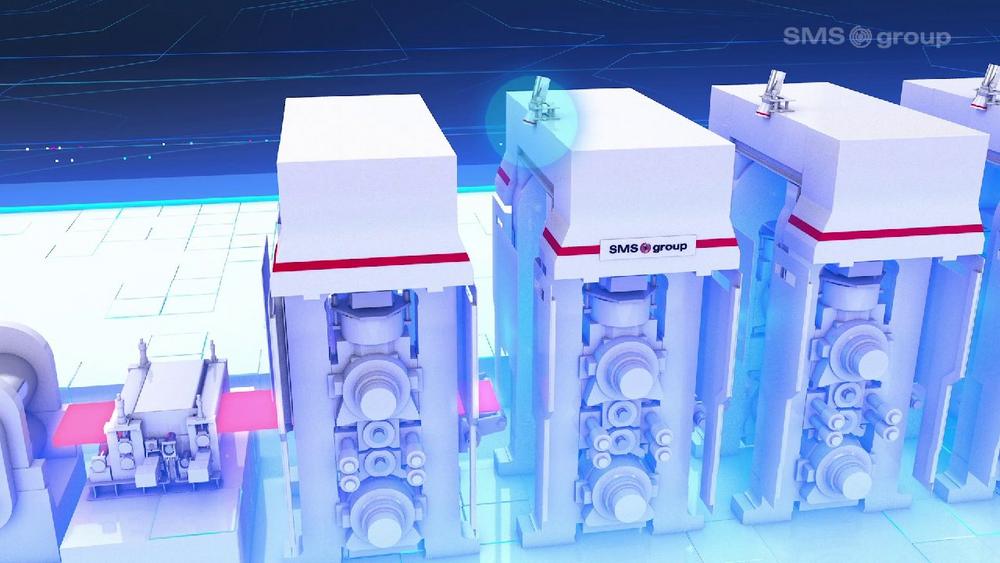

With a focus on modernizing its seven-stand hot strip mill, Salzgitter Flachstahl GmbH has now successfully achieved a significant milestone with SMS group. Since 1963, the mill has been frequently upgraded with cutting-edge technologies, driven by a strategic collaboration with SMS group. This landmark project, completed in March 2025, involved the implementation of the sophisticated X-Pact® Centerline Control system, an integrated strip guiding control system.

The centerpiece of a comprehensive technology package ordered from SMS a year ago, this advanced automation solution optimizes the rolling process by automatically detecting and correcting lateral strip deviations using smart cameras. These industrial cameras, designed to withstand harsh environmental conditions, enable real-time adjustments to ensure precise strip alignment, thereby mitigating issues such as double-rolled strip edges, ripped tail-ends, and cobbles. Improvements in both wedge and strip position play a significant role when it comes to strip behavior.

Driven by Salzgitter’s ambition to enhance rolling stability and strip quality while minimizing unscheduled downtimes and manual steering corrections, the X-Pact® Centerline Control system is a fully automated solution that substantially boosts the overall production efficiency of the high-performance hot strip mill. The enhancements in product quality include uniform winding and thickness, reduced internal stresses, enhanced surface finish, and consistent material properties, all of which contribute to the final product’s high processability.

The integration of the X-Pact® Centerline Control system was seamless, with image processing running on a real-time system and values transmitted periodically to the level 1 automation system. Using the hydraulic gap control unit, the seven mill stands can be effectively managed, with all of them monitored via a user-friendly HMI system.

Thomas Rothe, head of the hot strip rolling mill at Salzgitter, expressed his satisfaction, stating, “This system has proven to be highly effective and has performed beyond our initial expectations.”

The feedback from satisfied customers highlights SMS’s ability to deliver exceptional results. This successful milestone is a testament to the enduring partnership and the shared vision of innovation and excellence within the industry. Salzgitter’s decision to partner with SMS was influenced by the latter’s technological leadership and comprehensive range of custom solutions. Sustainability, digitalization, and competence in meeting its customers’ specific requirements further solidified this partnership.

SMS group is renowned worldwide for its future-oriented technologies and outstanding service for the metals industry. The company applies its 150 years of experience and its digital know-how to provide the industry continuously with innovative products and processes – even beyond its core business – and generates worldwide sales of around 4 billion euros. SMS is the right partner for challenging projects and supports its customers throughout the lifecycle of their plants, enabling profitable and resource-efficient value creation chains. Paving the way for a carbon-neutral and sustainable metals industry is the company’s stated goal. As a global player with German roots, SMS takes responsibility for more than 13,500 employees.

SMS group GmbH

Am SMS Campus 1

41069 Mönchengladbach

Telefon: +49 2161 350-4449

http://www.sms-group.com

Fachpresse

Telefon: +49 2161 350-4449

E-Mail: thilo.sagermann@sms-group.com

![]()